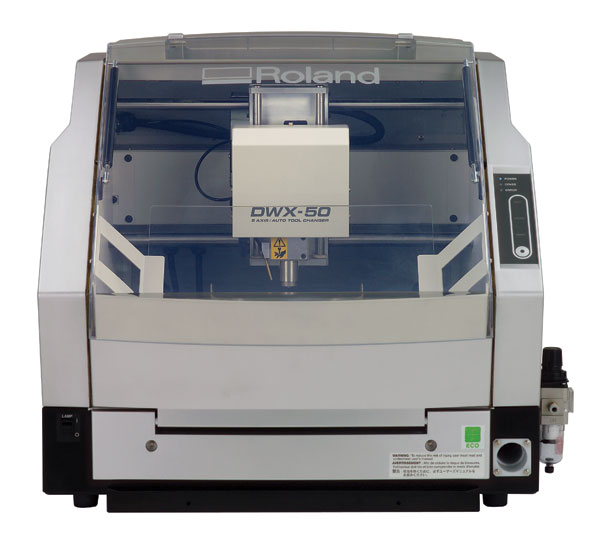

Roland DWX-50

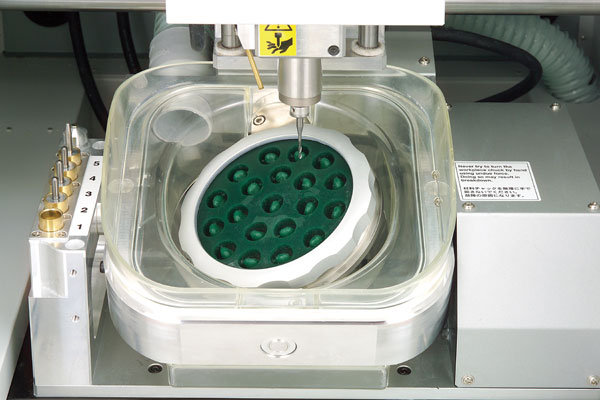

The Roland DWX 50 5-Axis milling unit has a footprint of only 656 x 656mm and height of only 557mm. The unit uses five axes simultaneous milling and so it is designed to mill on X, Y and Z axes, rotating blocks and discs of material 360 degrees in both clockwise and counterclockwise movements, as well as tilting materials forward and backward 20 degrees to support very complex cuts. 5 axes milling allows any type of dental restoration to be created. The five-station Automatic Tool Changer with a tool length sensor enables you to run multiple tools for one job or an entire disc unattended, changing the tool size and shape automatically when required. The integrated tool diagnostics feature notifies users if a tool was broken prior to completing a job, resulting in reduced time and material wastage. This is a great feature as the machine can be run through the night completely unattended. The unit is ideal for milling wax, zirconia and PMMA. The DWX-50 is able to cut materials quickly and with precision. For maximum flexibility in choice of materials, the DWX-50 is equipped with universal material clamps and adaptors that hold and cut a variety of industry standard material discs and blocks.

Roland DWX-50

| Indications | |

| Materials | |

| CAD Import Options | |

| Software | |

| File Format | |

| Wet or Dry | |

| Milling Axes | |

| Discs or Blocks | |

| Max Material Size | |

| Material Changer | |

| Automated Tool Changing | |

| Wet to Dry Swap Time | |

| Dimensions of Unit | |

| Weight of Unit | |

| Installation Requirements | |

| Training | |

| Ongoing Support | |

| Warranty | |

| States where support is available | |

| Country of Manufacture |

Roland DWX-50 - A Ceramics Ltd

Alan Bamford, director of Oldham-based dental laboratory, A Ceramics Ltd has embraced the digital future of dentistry by investing in two Roland DWX-50 dental milling machines.

A quick tour of the Roland DWX-50

Custom Automated Prosthetics (CAP) has developed an end-to-end integrated solution with the Roland DWX-50 dental milling system. This is a highly reliable and affordable 5-axis milling system which can reduce your milling center outsource costs significantly, even if you are only doing a few units per day.

Sponsored Links...

Upcoming Events... |

|---|

|

Jan 01 2025

TRIOS Care EXCLUSIVE: 1:1 Virtual Session (Book a day in 2025)Australia & New Zealand, AUSTRALIA |

|

Mar 12 2025

|

|

Mar 15 2025

Mastering Your Practice Exit StrategySydney, AUSTRALIA |

|

Mar 17 2025

Webinar - Digital Denture Study Club: Session 1Australia & New Zealand, AUSTRALIA |

|

Mar 19 2025

ITI Congress ColombiaBogota, COLOMBIA |

|

Mar 21 2025

SIDO International Spring MeetingFlorence, ITALY |

|

Mar 21 2025

ITI Congress UK & IrelandBirmingham, UNITED KINGDOM |

|

Mar 22 2025

|

|

Mar 24 2025

31st Global Dentists and Pediatric Dentistry Annual MeetingDubai, UNITED ARAB EMIRATES |

|

Mar 25 2025

IDS 2025Cologne, GERMANY |

|

Mar 29 2025

Mastering Your Practice Exit StrategyMelbourne, AUSTRALIA |

|

Apr 02 2025

Functional Dentistry Congress 2025Kyoto, JAPAN |

|

Apr 10 2025

New Orleans Dental Conference and LDA Annual Session 2025New Orleans, USA |

|

Apr 12 2025

ITI Congress Southern AfricaCape Town, REPUBLIC OF SOUTH AFRICA |

|

Apr 15 2025

Belarus Medica 2025 - 30th International Medical ForumMinsk, BELARUS |

|

Apr 15 2025

|

|

Apr 15 2025

Webinar - TRIOS Café: A-Z Cosmetic Workflow with TRIOSAustralia & New Zealand, AUSTRALIA |

|

Apr 17 2025

Dental Forum 2025London, UNITED KINGDOM |

|

May 01 2025

IAO Annual Meeting 2025 - International Association for OrthodonticsWashington D.C., USA |

|

May 08 2025

PNDC 2025Seattle, USA |

|

May 08 2025

39th Australian Dental CongressPerth, AUSTRALIA |

|

May 08 2025

TDA Meeting 2025San Antonio, USA |

|

May 12 2025

APDC 2025 - 46th Asia Pacific Dental CongressManila, PHILIPPINES |

|

May 14 2025

CSDA's 158th Charter Oak Dental MeetingUncasville, USA |

|

May 15 2025

NCDS 2025Myrtle Beach, USA |

|

May 16 2025

BDA 2025Birmingham, UNITED KINGDOM |

|

May 20 2025

GalMED 2025Lviv, UKRAINE |

|

May 21 2025

Dentima Krasnodar 2025Krasnodar, RUSSIA |

|

May 22 2025

C.O Life SummitBarranquilla, COLOMBIA |

|

May 22 2025

ICOMS 2025Singapore, SINGAPORE |

|

May 23 2025

Famdent Show Mumbai 2025Mumbai, INDIA |

|

May 26 2025

|

|

May 28 2025

|

|

May 28 2025

Buldental - Bulmedica 2025Sofia, BULGARIA |

|

May 29 2025

CUSCO 2025Urubamba, PERU |

|

May 30 2025

Nobel Biocare Global Symposium 2025Las Vegas, USA |

|

Jun 07 2025

Mastering Your Practice Exit StrategyBrisbane, AUSTRALIA |

|

Jun 09 2025

|

|

Jun 10 2025

PACK EXPO Southeast 2025Guadalajara, MEXICO |

|

Jun 11 2025

|

|

Jun 20 2025

Scottish Dental Show 2025Glasgow, UNITED KINGDOM |

|

Jun 21 2025

Mastering Your Practice Exit StrategyAdelaide, AUSTRALIA |

|

Jun 25 2025

IADR/PER 2025 - 103rd General Session & Exhibition of the IADRBarcelona, SPAIN |

|

Jun 27 2025

ICOI Asia Pacific Congress 2025Deagu, KOREA, SOUTH |

|

Jul 22 2025

MIDS 2025 - 8th Malaysia International Dental ShowPetaling Jaya, MALAYSIA |

|

Aug 01 2025

Digital Dentistry & Dental Technology 2025Sydney, AUSTRALIA |

|

Aug 07 2025

IDEX Egypt and Africa 2025Cairo, EGYPT |

|

Aug 07 2025

IndoHealthcare Expo 2025Jakarta, INDONESIA |

|

Aug 22 2025

HKIDEAS 2025Hong Kong, HONG KONG |

|

Aug 28 2025

ABSO Meeting 2025Hamilton Island, AUSTRALIA |

|

Sep 03 2025

AAPD 2025Kuta, INDONESIA |

|

Sep 09 2025

WID 2025 - Vienna International Dental ExhibitionVienna, AUSTRIA |

|

Sep 12 2025

|

|

Sep 13 2025

Mastering Your Practice Exit StrategySydney, AUSTRALIA |

|

Sep 17 2025

PharMed Cambodia 2025Phnom Penh, CAMBODIA |

|

Sep 19 2025

IADR 2025 - Asia/Pacific Region Annual MeetingNew Delhi, INDIA |

|

Sep 20 2025

Mastering Your Practice Exit StrategyMelbourne, AUSTRALIA |

|

Sep 25 2025

28th International Dental CongressDiyarbakir, TURKEY |

|

Sep 29 2025

PACK EXPO Las Vegas 2025Las Vegas, USA |

|

Oct 02 2025

IAO 2025Padova, ITALY |

|

Oct 02 2025

ITI Congress BrazilRio de Janeiro, BRAZIL |

|

Oct 09 2025

Pragodent 2025Prague, CZECH REPUBLIC |

|

Oct 15 2025

AAP 2025 - American Academy of PeriodontologyToronto, CANADA |

|

Oct 16 2025

Italian Dental Show - Colloquium Dental 2025Brescia, ITALY |

|

Oct 16 2025

DDS Global Congress 2025Venice, ITALY |

|

Oct 16 2025

ADOHTA-DHAA 2025 National CongressGold Coast, AUSTRALIA |

|

Oct 24 2025

National Osteology Symposium 2025Florence, ITALY |

|

Nov 05 2025

ITI Congress MexicoMérida, MEXICO |

|

Nov 06 2025

|

|

Nov 07 2025

ITI Congress ItalyBologna, ITALY |

|

Nov 08 2025

CDSS 2025Singapore, SINGAPORE |

|

Nov 14 2025

IDEC 2025Jakarta, INDONESIA |

|

Nov 20 2025

MCDC 2025 - Annual Mid-Continent Dental CongressSt Louis, USA |

|

Nov 28 2025

Greater New York Dental Meeting 2025 (GNYDM) - 101st Annual SessionNew York City, USA |

|

Dec 05 2025

8th Dental Expo 2025Lahore, PAKISTAN |

|

Mar 20 2026

ASO 2026 - The 30th Australian Orthodontic CongressMelbourne, AUSTRALIA |

|

Apr 17 2026

IDEM Singapore 2026Singapore, SINGAPORE |

|

Nov 27 2026

Greater New York Dental Meeting 2026 (GNYDM) - 102nd Annual SessionNew York City, USA |

|

Nov 26 2027

Greater New York Dental Meeting 2027 (GNYDM) - 103rd Annual SessionNew York City, USA |

|

Nov 24 2028

Greater New York Dental Meeting 2028 (GNYDM) - 104th Annual SessionNew York City, USA |

Thursday, 13 March, 2025